We’ve been wanting a way to test mini moto engines outside of their usual home — something that lets us tweak performance, try out fuel mixes, and eventually repurpose these engines for other builds. So we decided to build our own DIY engine test stand. Here’s how it went.

Step One: The Engine Hunt

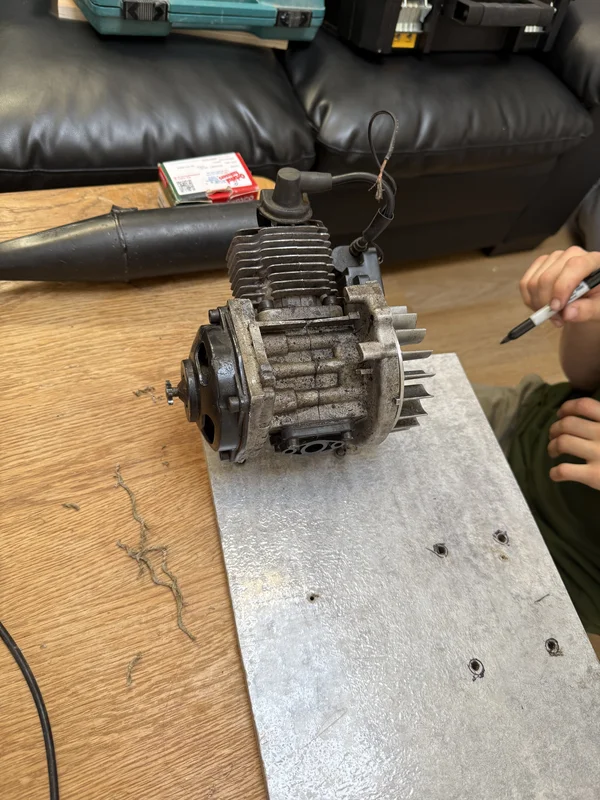

We started by digging through the infamous clear box of mini moto chaos — a treasure chest of half-assembled parts and oily bolts. Inside, we found a spare engine missing its spark plug and pull start. A quick rummage later and we had both, plus the carburettor and the bolts we needed to piece everything back together.

Elliot even came through with a spark plug that miraculously fit — found in his toolbox like a gift from the gods of two-stroke.

Step Two: A Test Stand with a Story

For the stand itself, we repurposed wood left behind by our landlord after a slightly questionable shower repair job. It felt right to give it a second life.

Disassembly wasn’t without drama — Ollie managed to put a drill bit through the edge of his hand while trying to pull out a stubborn screw. Luckily it was more of a scratch than a wound, but it earned a quick break and a re-evaluation of hand positioning.

We lined up the engine, drilled mounting holes, and added some improvised wooden legs to accommodate the protruding carburettor. Once bolted in, we reattached the exhaust and throttle cable. It was starting to look like something functional.

Step Three: Fuel Leaks and Improvised Solutions

With everything mounted, we filled the tank — and immediately watched the fuel pour out the bottom of the carb. Classic. Suspecting a stuck float, we stripped the carb back off, cleaned it thoroughly, and blasted the jets with carb cleaner.

Miraculously, that did the trick. It started up after a few pulls, and with some idle screw fiddling, we got it purring — or more accurately, jittering across the floor like a caffeinated hex bug.

Then we noticed the fuel tank was sitting right on top of the exhaust — not ideal if you’re into not catching fire. So we improvised a new tank: an upside-down plastic bottle, chopped and mounted to the stand, with the fuel hose threaded through the cap. Ugly? Maybe. Functional? Definitely.

The Result

We now have a working engine test stand that’s weirdly satisfying to look at and even more satisfying to run. Next up: experimenting with fuel mixes, ratios, and maybe even some performance mods.

Bonus: no major injuries (unless you count the drill incident), and we didn’t set anything on fire. A solid start.